The Pennsylvania Steel Company – Steelton, Pa.

1866 to 1917 (Pennsylvania Steel Co.), 1866 to Present

Owners: Pennsylvania Steel Company; Bethlehem Steel; International Steel Group; ArcelorMittal; Cleveland Cliffs.

Historical Significance: Pennsylvania Steel Company was America’s first steel company. In 1868, the site became the first in the U.S. dedicated exclusively to the process of making steel. The company also made the first steel rails in America for commercial sale. Today, the Steelton site (operated by ArcelorMittal) is one of only three rail producers in the Americas.

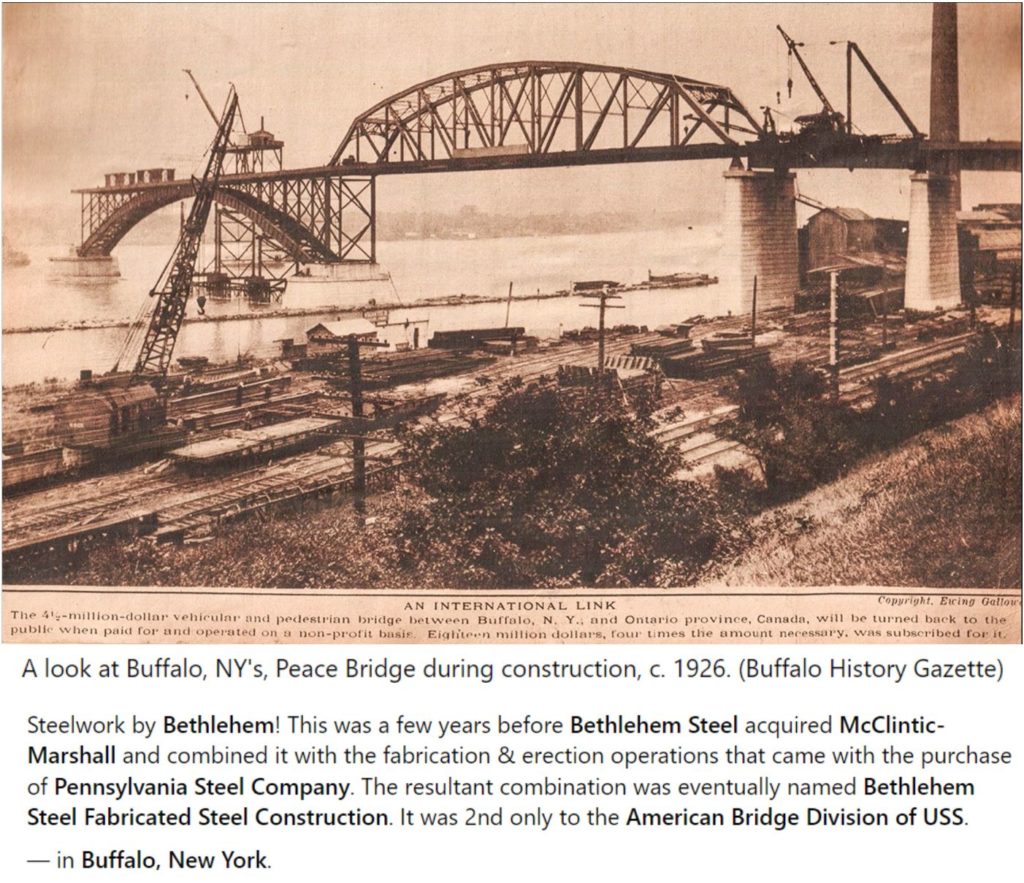

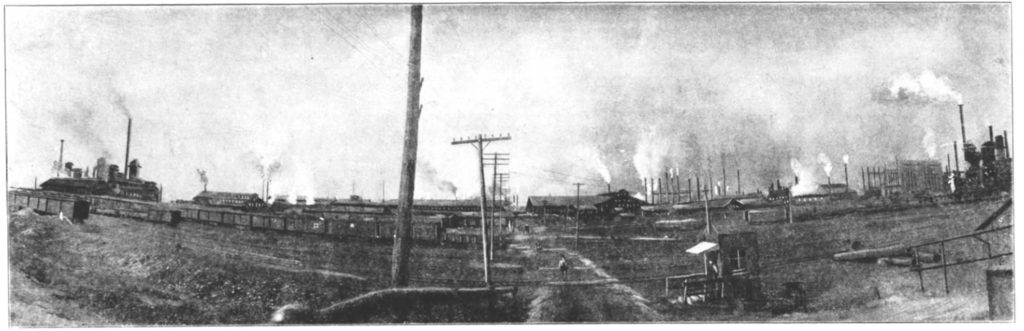

Beginning with the Pennsylvania Steel Company, which was organized in June 1865, the plant of which now covers 160 acres, one stands in wonderment at the marvelous strides made in the mechanical world. The construction of the steel plant at what is not the city of Steelton (for city it ought to be termed), was commenced in December, 1865, and was ready for operation in May 1867. On the 25th day of the same month, the first steel ingots ever produced in Pennsylvania by the Bessemer process were made. The rail mill of the Pennsylvania Steel Company went into operation May 15, 1868. The importance to the railroad interests of the country, and to all consumers, of the successful commencement, at these works, of the manufacture of steel rails has been very great, and probably no one can appreciate the value to the country of the business which began at these works at that date. During the first years of operation the steel ingots were hammered before rolling in the Forge Department, where they had what was at that time the largest steam hammer in the country. The practice of hammering was continued until December 1876, when the present Blooming Mill No.1 went into operation. Since that time the steam hammers have been employed in the production of forgings and other shapes of special steel. In 1875 the company increased its capacity for the production of steel by erecting an open hearth furnace plant. The original open hearth plant was later replaced by one of greatly increased capacity, and the capacity has been increased several times by the addition of new furnaces. The original Bessemer plant, known now as Bessemer No.1, had two converters, the nominal capacity of five tons each. In 1881 an additional Bessemer plant, known as Bessemer No.2, was completed and put in operation. This plant has three converters of ten tons capacity each, and was arranged and constructed on plans which secured great facilities for handling material and products, and enabled it to develop great capacity of production. The company commenced the erection of blast furnaces in 1872 to produce pig iron for their own purposes, and completed No.1 furnace in 1873, No.2 furnace in 1875, No.3 furnace in 1883, and No.4 furnace in 1884. These furnaces are of highly approved designs, with the Whitwell patent hot blast stoves, and have produced outputs of iron comparing favorably with any blast furnaces in the country. Rolling mills for making steel bars of the various sizes and shapes, known as “merchant bars,” were erected in 1882, the plant taking the name of “merchant mill,” the product of the same consisting of merchant bars, billets, rail splices, angles and various other shapes. This plant has been enlarged by the billet mill building, with a large amount of machinery used in finishing the product. In 1885 there was added to the Forge Department a train of rolls of the type known as “universal,” driven by a powerful reversing engine, for rolling special qualities of steel into slabs and blooms of dimensions required by manufacturers of plates, etc., and this branch of manufacture has been fully employed. In 1886 an additional mill, called Blooming Mill No.2,was erected for the preparation of special steel required by manufacturers of nails, etc., and has also produced a great product. The manufacture of switches, steel rail frogs, crossings, etc., commenced in 1872, and this branch having met with great encouragement from railway managers in various parts of the country, has been enlarged from time to time. A substantial and handsome brick building 478 feet long and 78 feet wide was erected in 1882, replacing the building previously used for this business, and still greater enlargement having become expedient there was erected a very large addition, consisting principally of one building 210 feet long, 125 wide; another building 144 feet long and 35 feet wide. These building have been fitted with the most approved appliances for the production of frogs, switches, &c., and the business has grown to very large proportions, conducted under the title of Frog, Switch and Signal Department. In 1893 a slabbing mill for rolling slabs, plates and other structural material was erected, still further adding to the immensity of the plant. The company next organized a department for the manufacture of bridges, viaducts, roofs, buildings and other constructions, under the title of Bridge and Construction Department. Several large buildings have been erected for the purposes of this department, and it has entered upon a very busy career. Departments for the manufacture and removal of various appliances were found necessary at n early day in the history of the company, and a foundry, machine shop and smith shop went into operation in 1867. These were enlarged from time to time with substantial buildings, which at the present day rank amongst the largest plants of this description in the State, with building appliances in all manner of machine tools and other appliances for the reproduction and repairs of the heaviest class of machinery used in the works. In 1867 the company’s yearly product of steel ingots was 1,005 tons; in 1890 it was 304,488 tons. This gives some idea of the company’s growth. In 1890 the product of one day was nearly equal to the whole year’s product of 1867. The total product of steel ingots from 1867 to 1895 was four million, twenty-six thousand, eight hundred and four tons!! Think of this, if you can, and pause while you think. There was a decrease in the output of the 1891, 1892, 1893 and 1894, owing in part to the general business depression and also to a change in the character of the product. A great proportion of the rails now manufactured are for electric roads, and are much more difficult to make than for steam roads. The immense acreage of the company lies between the Pennsylvania railroad and the Pennsylvania canal. The length of the plot is over a mile and a quarter, and the view presented to those passing in the trains of the Pennsylvania road is one of decided and unusual interest. The tremendous quantities of metal to be seen from the train invariably attract attention, and persons frequently imagine the metal to be held for speculation, until they learn that the monthly requirements are twenty-five to thirty thousand tons. The movement of the vast amount of material daily required in the works is a matter requiring extensive facilities, and the company has over twenty locomotives of various sizes plying upon tracks equal in extent of upwards of thirty miles of single track railroad. The freight cars received and dispatched in some weeks exceed 2,500 or 400 per day. The pay roll of the company embraces five thousand names, and the annual disbursements for labor is nearly two million dollars. There are over 20,000 persons who have their support directly from this company’s disbursements for labor alone, and when we consider the disbursements for materials, supplies, &c. and for the freight paid to the railroad companies carrying the materials, &c., and endeavor to estimate the extent to which the material interests of those in various ways related to or in some manner dependent on the successful prosecution of this immense enterprise, we may safely estimate the importance of this company’s affairs affects a population equal to that of many congressional districts. It was computed by a recognized statistician that the railroad tonnage due to the transportation of the materials and products of a similar and less important establishment for a year represented more ton miles than the business of the great Stat of Texas for a corresponding period. The works are reached by the tracks of the Pennsylvania railroad, also by the tracks of the Philadelphia & Reading railroad. This industry has given birth to a city. Steelton is the outgrowth of the Pennsylvania Steel Company. Twenty-one years ago the sit of the town was nothing but farm lands, to-day it is a bustling community that holds within her corporate limits several other large industries that would reflect credit upon any metropolis in the country, and which are known from the Atlantic to the Pacific on account of their various products. Steelton is a well built city, mostly of brick, it is also well paved and is equipped with gas, water, electric light and electric railway accommodations. The Steelton high school is one of the best structures in the State; there are palatial residences and comforts, and all the stores and commercial interests are thriving. Samuel Morse Felton founded the enterprise and organized the Pennsylvania Steel Company. He was born July 17, 1809. At the age of fourteen he was employed as a clerk in a grocery store in Boston, and while there fitted himself for Harvard College, from which he graduated in 1834, beginning the study of law. For the benefit of his health he soon adopted the profession of civil engineering, and in 1838 engaged in railroad construction in New England. In 1845 he became superintendent, and in 1871 he became president of the Philadelphia, Wilmington & Baltimore railroad, and removed to Philadelphia. Paralysis compelled him to retire in 1865 for a short time. After several months of rest, in connection with J. Edgar Thomson, president of the Pennsylvania Railroad Company, and others, he took up the manufacture of steel rails, and the result was the organization of the Pennsylvania Steel Company. Mr. Felton was elected president, and held that position during his life. He died January 24, 1889, aged nearly 80 years. He was a man of marvelous executive ability, and was deeply interested in the welfare of the company. His genial presence and wise counsel have been greatly missed by former associates, and his memory is highly honored by all who knew him in public and private life. The Pennsylvania Steel Company was fortunate in securing, in 1874, the services of Maj. Luther S. Bent as superintendent. From the date of his engagement by the company the history of the same has been one of continual progress and great prosperity. The devotion with which he managed the multi-sinuous affairs of the company has never been exceeded in any similar enterprise. By his grasp of its affairs, and his foresight, he has been enabled to conduct it with a success, the fame of which is world-wide. During the latter years of Mr. Felton’s life, Major Bent assumed the position of general manager and vice-president, and upon the death of Mr. Felton was chosen president and continued such until 1896 when Mr. Edgar C. Felton, son of the first president, was elected. The general superintendent of the company is Mr. Harry H. Campbell, who has charge of the practical affairs of the manufacturing departments, and upon his shoulders rests a great responsibility, which he assumes with confidence born of success. The president and general manager of the company, Mr. Edgar C. Felton, is the guiding spirit of the company’s affairs, a born executive, a master of intricate detail and is possessed of that spirit of public progress so essential to the commercial success of all communities.

Dauphin County Pennsylvania Genealogy Transcription Project Date of transcription: 13 Oct 2000.

The Pennsylvania Steel Company – 1902

Office Building Erected 1914